News

Inline vs Offline: How to Choose the Right Prod...

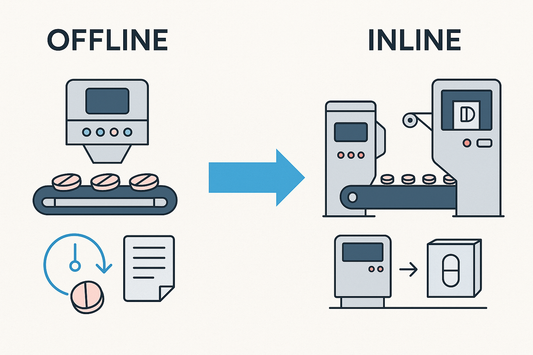

Inline reduces WIP and handling by syncing equipment along the line; offline adds flexibility for multi-SKU operations but introduces transfer and data stitching. This article provides a practical decision matrix—throughput,...

Inline vs Offline: How to Choose the Right Prod...

Inline reduces WIP and handling by syncing equipment along the line; offline adds flexibility for multi-SKU operations but introduces transfer and data stitching. This article provides a practical decision matrix—throughput,...

Why Laser Drilling Is Essential for Osmotic Tab...

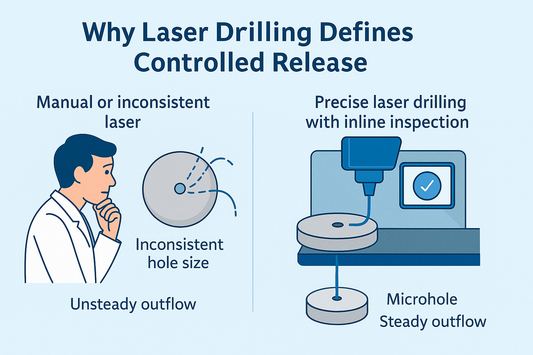

Consistent laser-drilled microholes are the key to stable osmotic tablet release curves. Variations in hole size, position, or quantity can cause release-rate shifts, dissolution risks, and BE failure. HUANGHAI’s K3-2...

Why Laser Drilling Is Essential for Osmotic Tab...

Consistent laser-drilled microholes are the key to stable osmotic tablet release curves. Variations in hole size, position, or quantity can cause release-rate shifts, dissolution risks, and BE failure. HUANGHAI’s K3-2...

Gradient Hot-Air Drying: The Key to ODF Yield a...

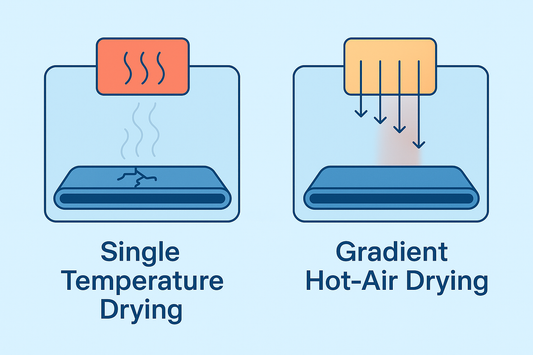

Efficient drying determines the quality and yield of ODFs and transdermal patches. HUANGHAI’s patented gradient hot-air drying system prevents cracks, curling, and solvent residue by gradually increasing temperature with natural...

Gradient Hot-Air Drying: The Key to ODF Yield a...

Efficient drying determines the quality and yield of ODFs and transdermal patches. HUANGHAI’s patented gradient hot-air drying system prevents cracks, curling, and solvent residue by gradually increasing temperature with natural...

Doctor-Blade vs Slot-Die: Choosing the Right Co...

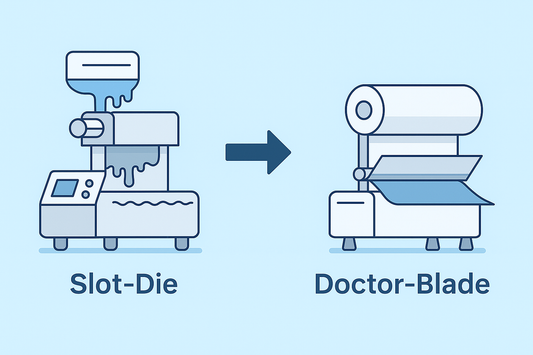

Coating method determines uniformity, stability, and scalability for ODFs and transdermal films. This article compares doctor-blade and slot-die, explains common failure modes with high-viscosity formulations, and shows why HUANGHAI adopts...

Doctor-Blade vs Slot-Die: Choosing the Right Co...

Coating method determines uniformity, stability, and scalability for ODFs and transdermal films. This article compares doctor-blade and slot-die, explains common failure modes with high-viscosity formulations, and shows why HUANGHAI adopts...

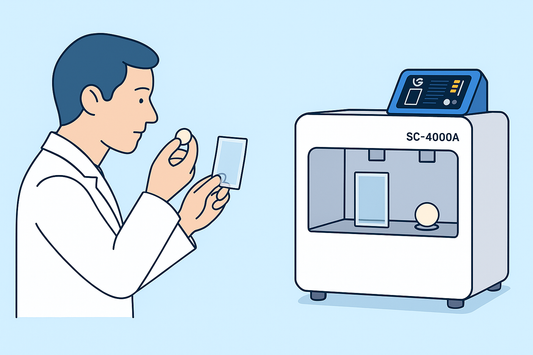

Transparency Testing: Ensuring Both Appearance ...

Transparency is more than appearance—it reflects consistency, stability, and quality in films, capsules, and tablets. The SC-4000A Transparency Tester quantifies optical clarity with precision sensors, enabling labs and production teams...

Transparency Testing: Ensuring Both Appearance ...

Transparency is more than appearance—it reflects consistency, stability, and quality in films, capsules, and tablets. The SC-4000A Transparency Tester quantifies optical clarity with precision sensors, enabling labs and production teams...

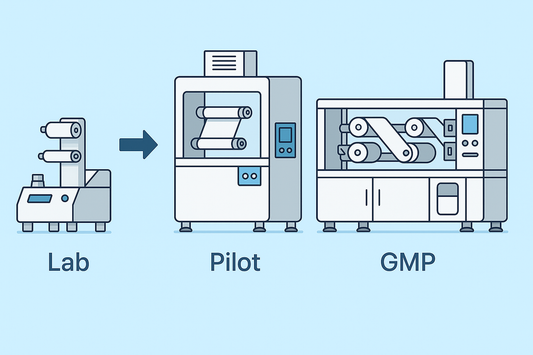

From Lab to Process Validation: The Value of Ex...

Lab-scale coating is the practical bridge between concept and process validation. This post explains why experimental coaters matter, common pain points with using pilot/production machines too early, and how the...

From Lab to Process Validation: The Value of Ex...

Lab-scale coating is the practical bridge between concept and process validation. This post explains why experimental coaters matter, common pain points with using pilot/production machines too early, and how the...