Transparency Testing: Ensuring Both Appearance and Quality in Pharma Products

Share

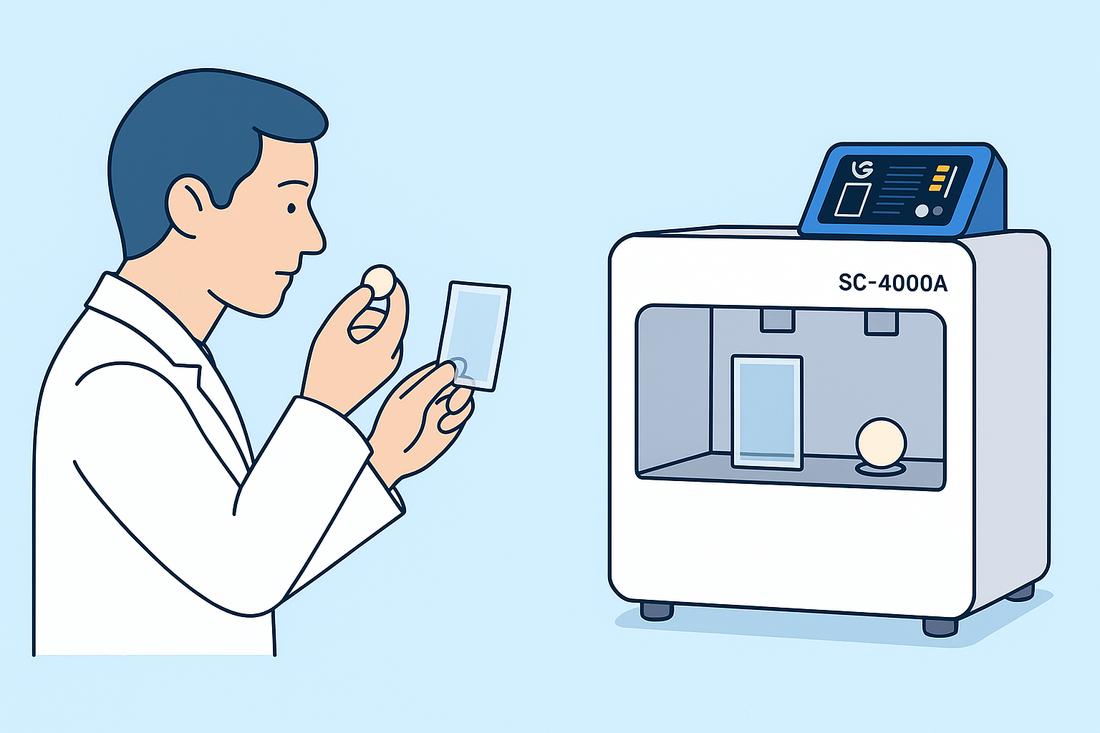

Summary: In pharmaceuticals and functional foods, appearance is not just about aesthetics—it can also impact stability and dissolution. Transparency testing for films, capsules, and tablets is now a vital quality control step. The SC-4000A Transparency Tester enables quantifiable, standardized, and efficient evaluation of product clarity.

Introduction

From oral thin films to hard capsules and coated tablets, appearance matters for both patient confidence and regulatory compliance. Transparency testing ensures batch-to-batch consistency, helps detect process variations, and provides objective data that manual visual inspection cannot achieve.

Why transparency testing matters

- Appearance consistency: Verifies uniform transparency across batches, supporting market competitiveness.

- Process stability: Transparency is linked to film or tablet thickness and uniformity, reflecting process control.

- Regulatory compliance: Pharmacopeias and standards increasingly require appearance testing as part of QC.

Industry pain points

- Subjective manual observation: Human eye judgment is inconsistent and non-quantifiable.

- Lack of standardization: Different labs apply varying methods, making results hard to compare.

- Low efficiency: Manual testing cannot support rapid R&D or production throughput.

HUANGHAI’s solution: SC-4000A Transparency Tester

The SC-4000A Transparency Tester brings objectivity and efficiency to appearance testing:

- High-precision sensors: Quantifies transparency, eliminating subjective errors.

- Automated detection: Delivers quick, reproducible results suitable for QC and production.

- Broad applicability: Compatible with oral films, capsules, thin tablets, and other dosage forms.

Manual vs. automated transparency testing

| Aspect | Manual Observation | SC-4000A Transparency Tester |

|---|---|---|

| Accuracy | Subjective, inconsistent | Objective, quantified data |

| Repeatability | Low, operator dependent | High, standardized results |

| Throughput | Slow, single-sample focus | Fast, suited for lab & production |

Compliance & value

- Standardizes appearance testing: Provides reliable and comparable results across labs.

- Supports R&D optimization: Offers quantifiable data to refine coating and film processes.

- Enhances consumer trust: Ensures visual consistency and strengthens product quality image.

Recommended equipment

Key takeaway

Transparency is both a visual and quality attribute. With the SC-4000A Transparency Tester, pharmaceutical companies can quantify transparency, reduce variability, and bring greater reliability to R&D and production QC workflows.