From Lab to Process Validation: The Value of Experimental Coaters in Film Development

Share

Summary: For ODFs and transdermal films, coating quality sets the ceiling for product performance. A lab-scale coater gives R&D teams a flexible, low-cost environment to screen formulations, tune parameters, and build a defendable data path toward pilot and GMP production.

Introduction

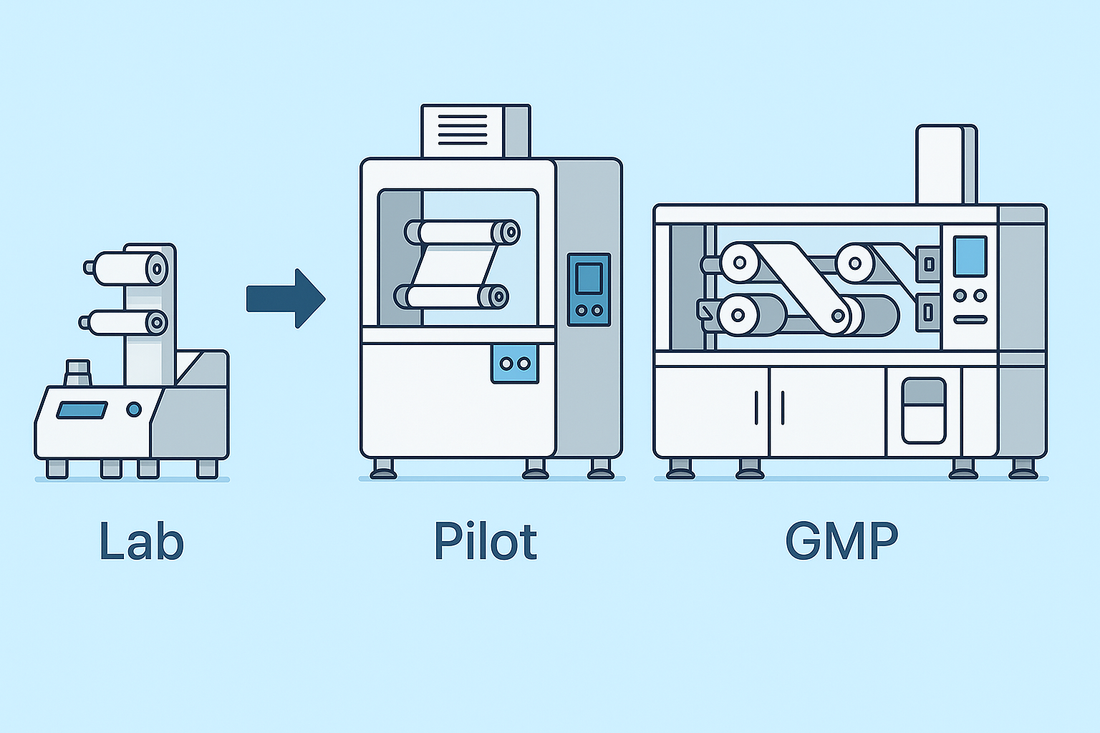

In oral dissolvable films (ODFs), transdermal patches, and other film-based dosage forms, coating is the core unit operation. Jumping directly to pilot or production tools increases risk, cost, and iteration time. An experimental coater lets you trial small batches, map design spaces, and de-risk scale-up.

Why lab-scale coating matters

- R&D starting point: Produce small batches early to compare formulations and run initial performance tests.

- Process exploration: Systematically optimize coat weight, drying temperature, and substrate compatibility.

- Cost control: Avoid expensive trials on pilot/production assets and reduce material waste.

Industry pain points

- High experimental cost: Early trials on large machines consume material, time, and utility budget.

- Limited flexibility: Production tools are not designed for frequent condition changes.

- Scale-up gap: Poor continuity between R&D settings and pilot/GMP parameters.

HUANGHAI’s solution: BY-300A Experimental Coating Machine

The BY-300A Experimental Coater is purpose-built for laboratory R&D and small-batch trials.

- Agile small-batch prep: Rapid iteration for different formulations and substrates.

- Adjustable parameters: Doctor-blade coating with tunable process settings to study coating windows.

- Compact footprint: Lab-friendly, easy to operate, quick to clean and reconfigure.

Lab vs. Pilot/Production: Where the BY-300A Fits

| Aspect | Pilot/Production Line | BY-300A Experimental Coater |

|---|---|---|

| Changeover & setup | Slow, costly | Fast, low-cost |

| Iteration speed | Limited (fewer trials/day) | High (many trials/day) |

| Material consumption | High | Low (small batches) |

| Parameter mapping | Narrow windows explored | Broad, efficient DoE screening |

| Scale-up readiness | Risk of late surprises | Generates data to inform pilot/GMP |

Compliance & value

- Faster process verification: Validate coating conditions at small scale before PPQ/validation.

- Data continuity: Build a traceable history from R&D to scale-up for audits and submissions.

- Lower total cost: Reduce rework, scrap, and machine downtime at later stages.

Recommended equipment

Key takeaway

For film-based dosage forms, an experimental coater like the BY-300A provides the agility R&D needs to explore formulations, define process windows, and create the data backbone that de-risks pilot and GMP-scale validation.