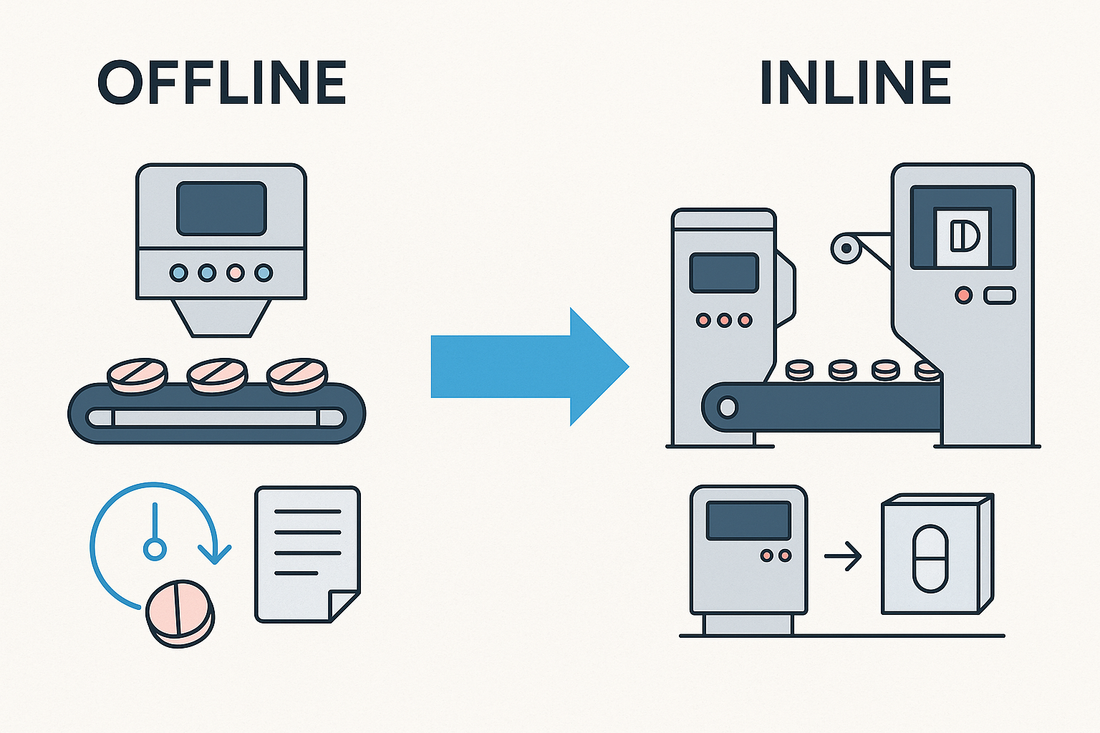

Inline vs Offline: How to Choose the Right Production Architecture in Pharma

Share

Overview: Greenfield projects often favor inline layouts to minimize handling and WIP. Retrofit plants or multi-product flexible lines frequently prefer offline stand-alone units. The right choice depends on throughput, changeover frequency, cleanliness strategy, validation scope, and budget constraints.

Key trade-offs

- Throughput & takt time: Inline equipment must synchronize with upstream and downstream steps (e.g., compression, coating, packaging). Offline units decouple takt, but add one step of transfer and WIP control.

- Changeover & flexibility: For high-mix, frequent format changes, offline assets can be shared and scheduled. Inline is highly efficient in steady SKUs, but changeover windows must be tightly engineered.

- Cleanliness & cross-contamination: Inline simplifies a unified air-handling and dust-control strategy. Offline requires added WIP protection, sealed transfer, and robust SOPs for movement between rooms.

- Validation scope: Inline demands cross-equipment interlock and data integrity validation. Offline has clearer boundaries per machine, but increases data consolidation effort.

- Investment & retrofit constraints: Existing space, utilities, and building services often drive the initial selection.

Decision matrix (practical guidance)

| Scenario | Inline | Offline |

|---|---|---|

| Single SKU, high throughput | Best fit — synchronized takt, lowest WIP | Possible but less efficient |

| Multi-SKU, frequent changeovers | Efficient when changeover windows are short & predictable | Best fit — shareable asset, time-sliced scheduling |

| Greenfield cleanroom strategy | Best fit — unified dust/negative pressure control | Requires sealed transfer SOPs |

| Retrofit with tight space/utilities | May require major rework | Best fit — stand-alone machine, minimal tie-ins |

| Validation complexity | Broader (interlocks, data flow across units) | Clear boundaries; more data stitching |

| WIP & material flow | Lowest WIP, fewer touches | Added transfer & WIP control |

HUANGHAI’s approach (works both ways)

Whether inline or offline, the goal is repeatable takt, cleanability, and data integrity. HUANGHAI’s K3-2 Laser Drilling System supports both architectures with mechanical/electrical handshakes and standardized data models.

- Inline integration: K3-2 synchronizes via digital I/O, fieldbus, or Ethernet triggers with upstream compression and downstream coating/packaging for stable takt and minimized WIP.

- Offline flexibility: Rapid change-parts, recipe/parameter set management, and sealed enclosure with dust extraction enable fast format swaps and robust cleanliness during transfer.

- Unified data: Standardized batch records (drill presence, diameter, position, images) export to MES/ERP for audit-ready traceability—identical formats in both inline and offline deployments.

- Cleanroom strategy: Inline supports central dust/negative-pressure control; offline provides independent enclosure sealing and docking interfaces to reduce cross-contamination risks during movement.

Practical pathways

- Stable, high-volume program: Prefer inline from day one; engineer changeover windows and line interlocks early.

- High-mix, small-batch portfolio: Prefer offline; share the K3-2 across products with scheduled time slots and recipe governance.

- Transition phase: Start offline with pre-engineered interfaces; merge into inline when volume stabilizes.

Conclusion

“Inline = efficiency” and “offline = flexibility” are helpful rules of thumb—but the best choice comes from a structured decision matrix across throughput, changeover, cleanliness, validation, and investment. By reserving integration interfaces and a unified data model, your line can evolve without re-validating fundamentals.