Why ODF Projects Need “Equipment Power” to Scale from Lab to GMP

Share

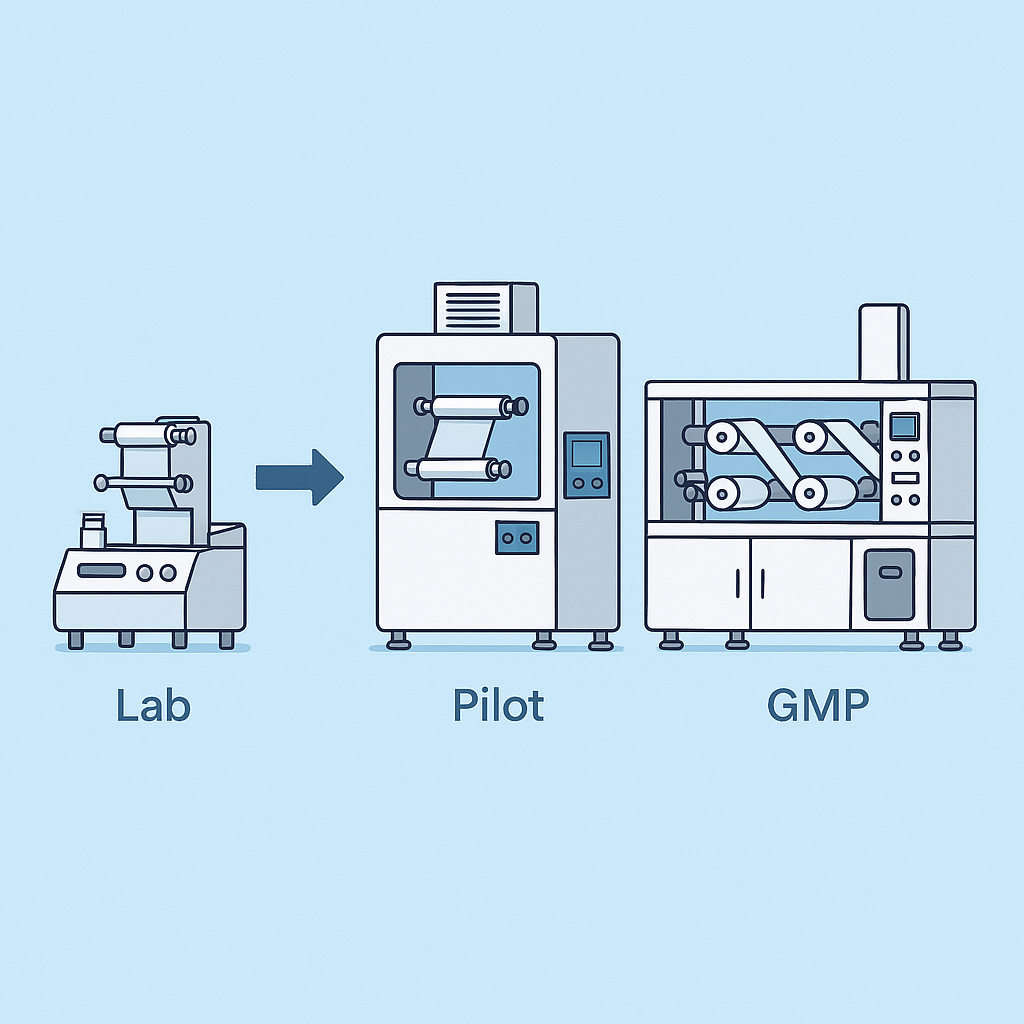

Many oral dissolvable film (ODF) projects succeed in the laboratory stage, but struggle when transitioning to GMP-scale production. Issues such as unstable films, inconsistent content, drying failures, and sudden drops in yield are common. One root cause is the technology gap between lab-scale and production-scale equipment. To achieve a smooth R&D-to-GMP transition, strong “equipment power” is needed to bridge the gap.

Common “R&D Disconnection” Problems

- Lab coating methods differ from production-scale machines, making parameters invalid

- Drying, tension control, and liquid supply systems are not aligned with actual production

- Lack of in-line detection systems, leading to non-traceable and non-auditable data

- Lab environments often fail to meet GMP cleanliness standards, limiting regulatory support

How Equipment Supports the Lab-to-GMP Transition

- Adopt pilot equipment such as MJ150-L, designed with the same principles as GMP machines, to validate scale-up processes in advance

- Equip systems with in-line thickness measurement, automatic tension control, and closed liquid supply for consistent data

- Enable data collection and export functions to meet audit trail requirements

- Record complete process parameters to support registration and export filing

Recommended Equipment:

HUANGHAI’s Lab-to-GMP Solutions

HUANGHAI offers a complete equipment ecosystem covering R&D, pilot, and commercial GMP stages:

- Lab-scale: MJ100 small coating lab system (optional)

- Pilot-scale: MJ150-L, enabling reproducible parameter migration for scale-up

- Commercial GMP: MJ150 with output up to 20,000 strips/hour, fully GMP-compliant

- Seamless integration with testing instruments, enabling a “manufacturing + testing” traceability loop

Conclusion

Success in ODF projects is not only about formulation — it is about process control and equipment alignment. Deploying pharmacopeia-grade pilot equipment and scale-up strategies early is the key to efficient market entry and successful regulatory approval.