The Value of Modular Design in Pharma-Grade ODF Production Lines

Share

Scale smoothly from R&D to commercial production while maintaining data continuity and GMP readiness.

Introduction

In pharmaceutical and functional food manufacturing, Oral Dissolvable Film (ODF) lines must support a full lifecycle—from early R&D and pilot validation to commercial-scale production. The challenge is ensuring a smooth transition between stages without re-engineering the process or duplicating investments. A modular ODF production design addresses this by enabling stepwise expansion on a common technical backbone.

Why Modular Design Matters

- Lower upfront investment: Start with pilot or mid-scale modules instead of a full large-scale line.

- Support process validation: Validate on a pilot line first, then scale up with consistent principles.

- Flexible expansion: Add or swap modules (coating, drying, slitting, packaging) as capacity grows.

Common Industry Pain Points

- One-size-fits-all lines: Different equipment for R&D, pilot, and commercial stages leads to repeated CAPEX.

- Process gaps across scales: Parameter drift between small and large equipment complicates registration and validation.

- Long scale-up cycles: Without modularity, every expansion requires fresh procurement, installation, and commissioning.

Huanghai’s Modular Approach

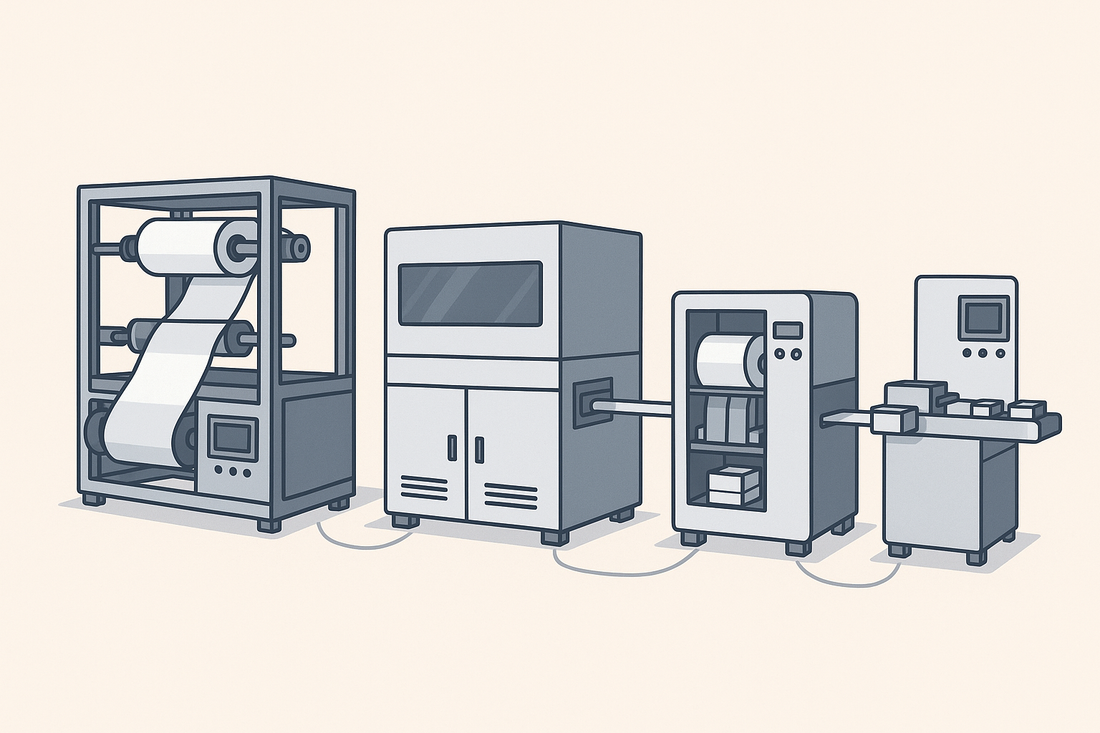

- Modular line layout: Core stages—coating, drying, slitting, and packaging—can be deployed in phases to fit current needs.

- Smooth R&D→commercial transfer: The pilot model MJ150-L and the commercial model MJ150 share the same process logic, improving data comparability and continuity.

- Reduced validation risk: Consistent design principles help minimize variability during scale-up and support GMP audits.

Quality & Compliance Value

- Traceability & consistency: Maintain aligned controls and documentation across stages.

- Registration-ready data: Generate continuous, comparable data sets for process validation and filing.

- Lifecycle agility: Improve flexibility and cost efficiency from development through commercialization.

Recommended Equipment

MJ150-L — Pilot/R&D Coating Machine

- Designed for development and pilot validation

- Process logic aligned with MJ150 for data continuity

MJ150 — Commercial Coating Machine

- Commercial-scale output for ODF and solvent-based patch films

- Built for GMP environments and scalable operations

MJF180 — ODF Slitting & Packaging

- Precise slitting and single-dose packaging

- Supports efficient downstream operations and stability

Conclusion

Modular design brings flexibility, scalability, and compliance support to pharma-grade ODF manufacturing. Each step—from R&D to commercial production—can progress on the same technical logic, reducing investment risk, shortening expansion timelines, and accelerating the journey from development to market.