How to Build a Modular ODF Production Line for Multiple Dosage Strengths

Share

Oral dissolvable film (ODF) projects can vary widely in dosage: some formulas carry only micrograms of actives (e.g., pediatric bedtime products), while others—including patch-like high-load films—require tens of milligrams or higher concentrations. To serve “product diversity” and “regulatory consistency” at the same time, a flexible, scalable, and modular ODF line is the most reliable path forward.

Why Your ODF Line Must Adapt to Different Dosages

- High-dose products demand thicker films and highly uniform content distribution.

- Low-dose products require ultra-precise thickness control and highly stable coating.

- Drying time, packaging format, and cut size will differ by product & market claim.

Fixed, single-purpose lines struggle with fast product switching—reducing capacity utilization and limiting registration flexibility. A modular design lets you reconfigure quickly while keeping validation intact.

Huanghai’s Modular ODF Architecture

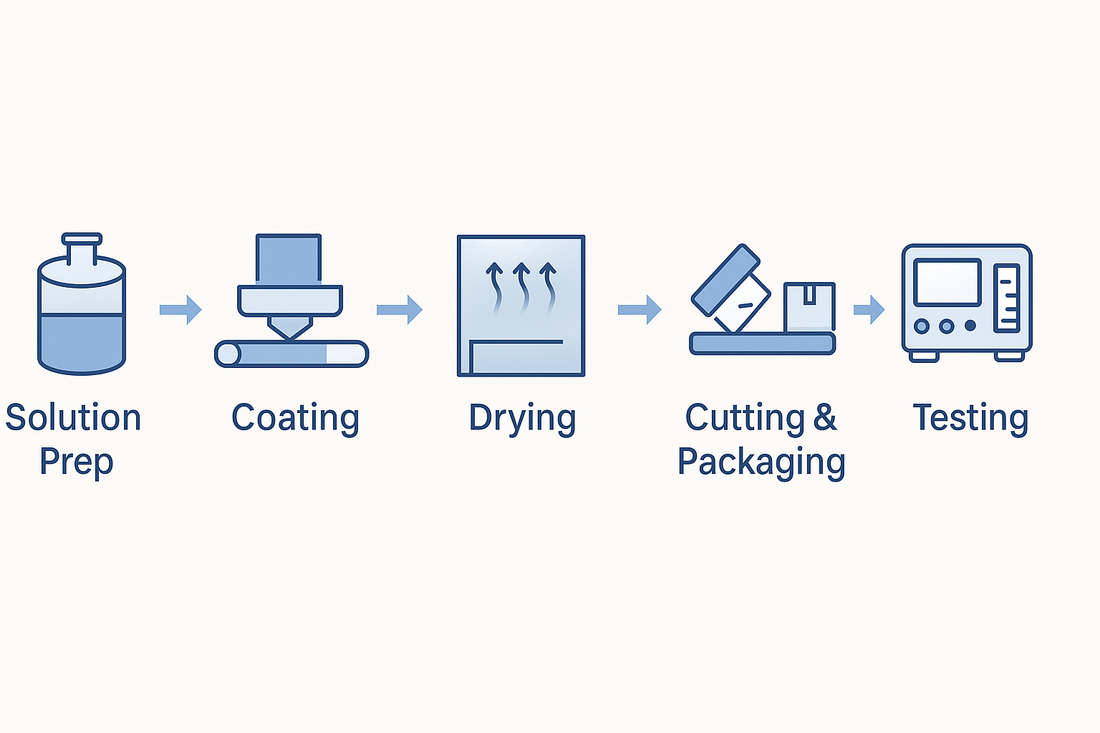

We design around five functional blocks: solution prep → coating → drying → cutting & packaging → testing. Below are the core modules most teams combine from pilot to commercial scale.

Module 1 — Multi-Spec Coating (MJ150 / MJ150-L)

MJ150 & MJ150-L provide adjustable mechanics for width and film thickness, enabling fast adaptation across low- and high-dose runs.

- Adjustable width & thickness to match target dosage and strip size.

- Slot-die head compatible with a wide viscosity range to stabilize coat weight.

- Gradient hot-air drying minimizes solvent migration and crystallization in high-load formulas.

Module 2 — Flexible Cutting & Packaging (MJF180)

MJF180 converts coated reels into single-dose pouches with rapid SKU switching.

- Interchangeable knife heads for different film sizes and edge quality.

- Packaging material agility (aluminum foil, PE, laminates) to meet stability needs.

- Inline add-ons: coding/printing, check-weighing, waste rejection for faster line release.

Module 3 — Common Testing Bench

Use a shared set of pharmaceutical testing instruments across products to streamline validation and audits.

- Cross-product utility: disintegration tester, thickness gauge, moisture analysis, etc.

- Validation support for multiple SKUs while keeping one data backbone.

- Rapid method switching to improve lab throughput and shorten release time.

Where a Modular Line Shines

- CDMOs: frequent client turnover, broad spec coverage, fast line reconfiguration.

- Pilot/registration teams: generate multiple dosage samples for US/EU submissions.

- Functional food brands: rapid flavor/strength iteration to capture niches.

- R&D hubs: study how formulation changes impact dose distribution and uniformity.

Quick Configuration Map

| Target Dosage | Recommended Coating | Drying Focus | Cut & Pack | Key QC |

|---|---|---|---|---|

| Microgram–Low mg | MJ150-L with tight gap control | Stable gradient; avoid over-drying | MJF180 fine-cut, tight pouch | Thickness uniformity, content uniformity |

| Medium–High mg | MJ150 with wider coat; higher viscosity | Gradient to limit migration | MJF180 with robust laminate | Weight check, moisture, disintegration |

Takeaway

Modularity is more than a mechanical concept—it’s the backbone of flexible, compliant ODF manufacturing. Huanghai supports phased combinations from single machine to full line, helping teams build repeatable, switchable, and continuously scalable capacity—one investment, many returns.

FAQ

Q1. How fast can we switch SKUs?

With predefined presets (die-lip gap, speed, drying profile, knife set), changeovers can be completed in hours rather than days.

Q2. How do we keep validation intact across different dosages?

Use a common URS/FDS backbone, shared testing instruments, and documented parameter windows; only re-validate the blocks impacted by change.

Q3. Which module should we start with?

Pilot with MJ150-L for dose-sensitive work, then scale with MJ150 and integrate MJF180 when commercial packaging is required.

Need a tailored configuration? Contact us to map your dosage range, film size, and regulatory targets.