Efficient Coating and Sterile Packaging Solutions for Transdermal Patches

Share

How to Achieve Efficient Coating and Sterile Packaging for Patch Products?

With the widespread application of transdermal patches, cooling patches, fever-reducing patches, and therapeutic patches in the pharmaceutical and health sectors, manufacturers face two main challenges in production:

- How to achieve uniform coating of high-viscosity liquids?

- How to balance production efficiency with sterile requirements for final packaging?

1. Efficient Coating: Focus on “Control” and “Adaptability”

Patch formulations are usually high-viscosity systems containing volatile components, requiring precise coating uniformity and thickness control. Common issues include edge build-up, thinning in the middle, and bubble formation.

Solutions include:

- Adopting dual doctor blade or multi-roll coating systems to enhance leveling ability.

- Integrating automatic tension control systems to keep film tension stable under high temperatures.

- Using enclosed circulation liquid supply systems to avoid air entry and control liquid temperature.

- Utilizing ducted airflow design to create a natural drying gradient, reducing shrinkage after coating.

The MJ150 ODF Solvent-Based / Transdermal Patch Film Making Machine supports continuous coating of viscous patch formulations, with coating thickness accuracy controlled within ±0.02 mm. For laboratory or small-scale R&D, the MJ150-L ODF Film Coating Machine offers similar precision with flexibility for testing environments.

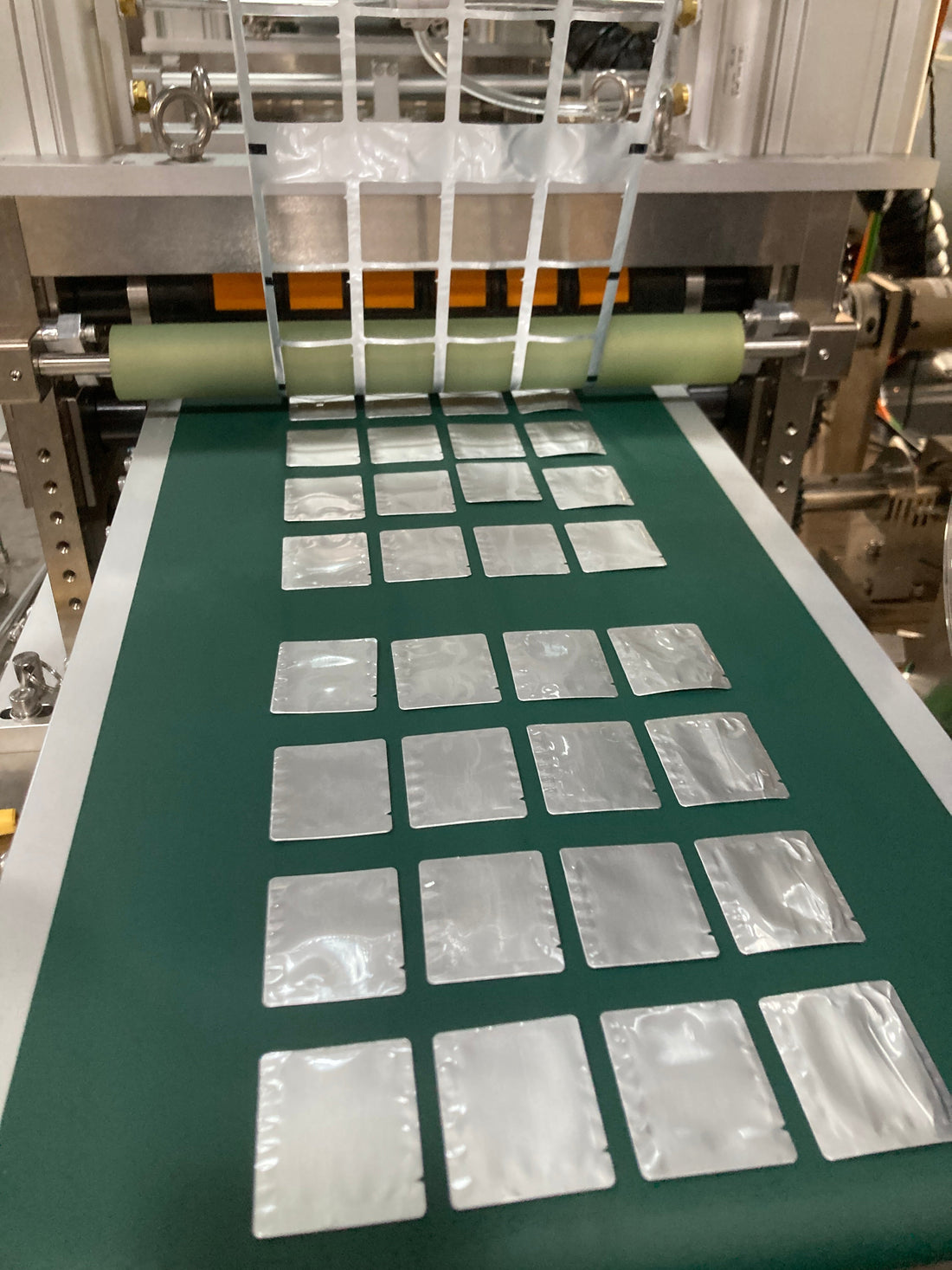

2. Sterile Packaging: Balancing “Cleanliness” and “Production Pace”

Patch products are mostly for skin contact or external medical use, requiring specific cleanliness levels and ensuring no contaminants enter during packaging.

Recommended solutions include:

- Using enclosed cutting and transfer systems to avoid excessive exposure of the film to air.

- Integrating HEPA-filtered hot air systems to reduce particle concentration in the packaging area.

- Combining vision inspection systems with automatic rejection devices to ensure defective patches are removed before final packaging.

- Installing laminar flow purification or ozone sterilization modules at the discharge point to enhance sterility assurance.

The MJF180 ODF Film Cutting and Packaging Machine can be equipped with cutting, vision inspection, automatic rejection, and edge-sealing modules, making it ideal for sterile packaging of medical patches and small-dose ODF products.

Conclusion

The patch product market holds huge potential but places higher demands on process integration and cleanliness assurance. Only by ensuring “control” throughout the entire process—from raw liquid coating to final sterile packaging—can companies achieve standardized, efficient, and low-contamination production systems.

HUANGHAI provides end-to-end patch solutions from R&D and pilot testing to commercial-scale production, helping clients reduce trial-and-error costs and quickly enter the health and wellness market.