How to Ensure Process Consistency When Scaling ODF from Lab to Mass Production

Share

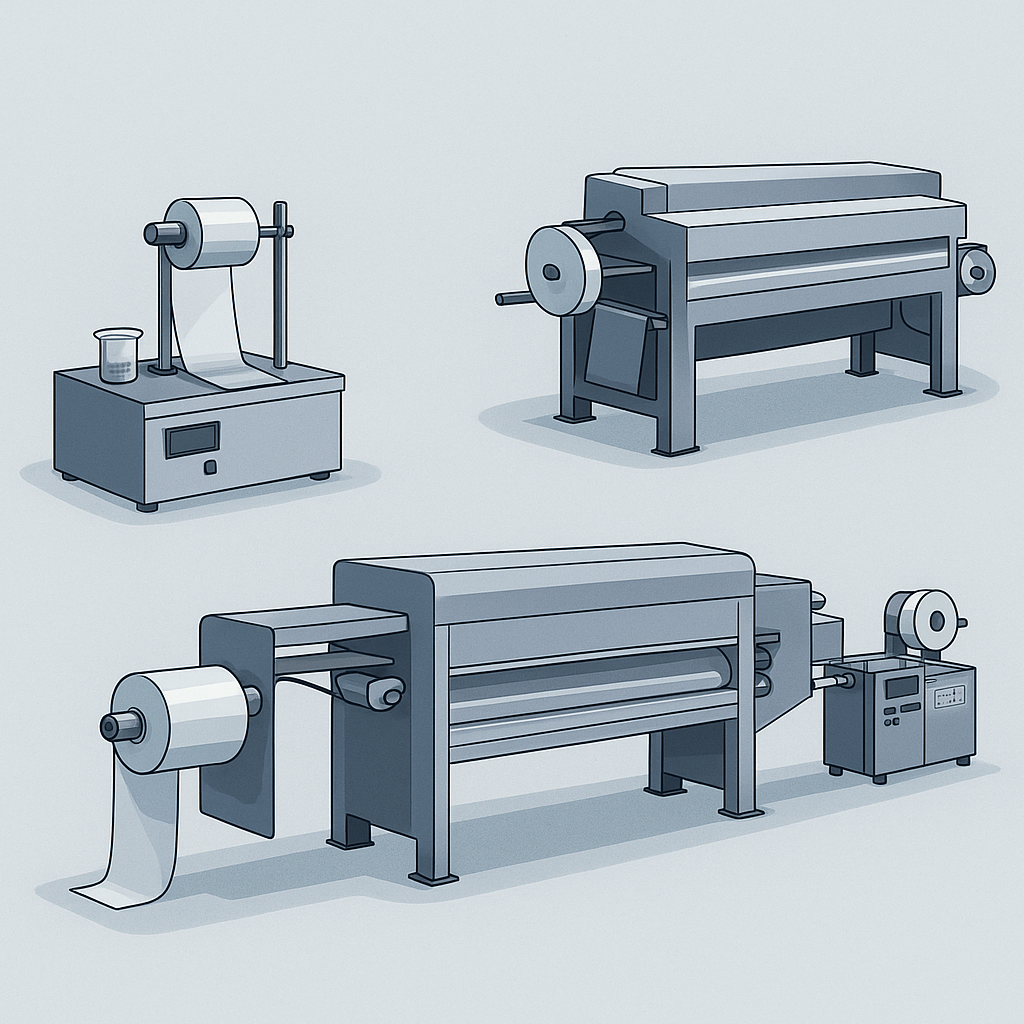

Many Oral Dissolvable Film (ODF) projects pass laboratory validation, yet struggle at pilot or commercial scale. Symptoms include shifts in film properties, content drift, abnormal drying, and falling yields. The underlying cause is often a loss of process consistency during scale-up. Achieving seamless migration from lab to mass production depends on equipment controllability and module reusability.

Common Control Gaps During ODF Scale-Up

- Unstable liquid feed: manual dripping in the lab vs. closed-loop pumping in production

- Large tension swings: wider web widths amplify uneven tension, causing wrinkles or breaks

- Uneven drying: long hot-air paths at scale lead to localized overheating or under-drying

- Inconsistent thickness: lack of in-line thickness monitoring hides edge-to-center variation

How to Achieve “Steady-State” Scale-Up

- Choose equipment with a controllable slot-die (coating die) and automatic tension control to maintain constant web tension across stages.

- Apply a gradient hot-air drying design to prevent stress shocks that degrade film performance.

- Integrate in-line thickness measurement (e.g., IR or laser) to dynamically correct coat weight.

- Implement digital parameter management—capture, record, and export data to enable cross-stage comparison and traceability.

Recommended equipment and pages:

HUANGHAI’s Process-Consistency Control Approach

- Unified architecture: R&D, pilot, and production platforms share the same slot-die + airflow path principles to ensure parameter portability.

- System-level feedback: closed-loop tension feedback and constant-feed mechanisms stabilize the entire process.

- Data modules: optional data acquisition enables cross-batch and cross-stage traceability.

- Manufacturing–testing loop: integrate dissolution/thickness testing with the main line to close the feedback loop.

Conclusion

Scaling ODF is not “just switching equipment”—it is about reusing proven process experience at larger scales. A highly consistent, verifiable equipment platform is the decisive foundation for commercial ODF production.