Scale Up Without Drift: Fleet Standardization for Laser-Drilled Osmotic CR Tablets

Share

Context: Once an osmotic CR tablet line expands to multiple shifts and rooms, tiny deviations in hole presence, size, and position start to surface. Audits intensify, documentation spreads across tools, and every new machine risks a new set of parameters. This post summarizes industry problems and a proven solution pattern for scaling without drift.

Industry Problems When Scaling Existing Capacity

- Cross-line variability: parameters diverge as more machines and operators come online.

- Sampling blind spots: off-line checks miss real-time shifts; non-conforming tablets can slip downstream.

- Documentation friction: batch records scattered; difficult to demonstrate consistency under GMP.

- Upgrade fatigue: adding capacity re-opens qualification and training every time.

The Solution Architecture We Provide

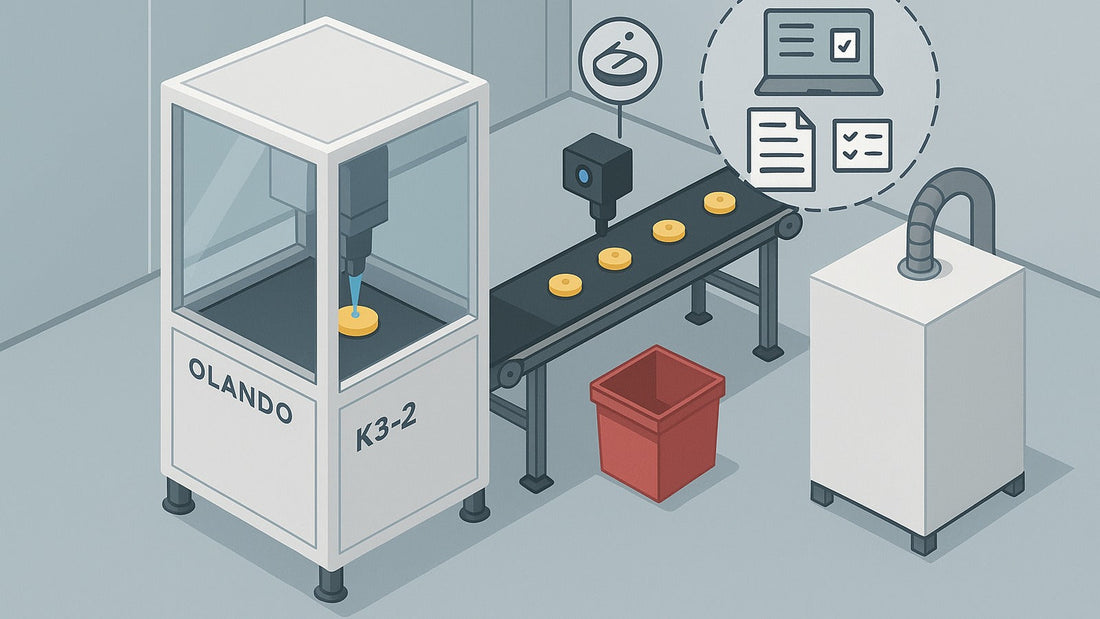

- Olando K3-2 laser drilling unit standardized across lines (single/double holes).

- Inline vision inspection of presence, size, position—closing the loop on quality at the point of drilling.

- Automatic rejection to contain non-conforming tablets immediately.

- Dust extraction & tablet handling designed for GMP cleanrooms.

- Electronic records with optional MES connectivity for batches, events, and alarms.

- Validation documents plus operator/maintenance training to keep shifts aligned.

Case Evidence: A 12-Machine Fleet in GMP Cleanrooms

A leading pharma manufacturer standardized on the Olando platform and expanded over time to 12 K3-series machines, all running in GMP cleanrooms. The fleet approach locked hardware/software baselines, unified vision/rejection logic, and centralized data via e-records (with optional MES integration). Result: consistent drilling quality across rooms and shifts with smoother capacity additions.

Implementation Checklist for Scale-Up

- Adopt a fleet baseline (same firmware, vision thresholds, rejection rules).

- Define URS-to-validation mapping for presence/size/position and challenge sets.

- Enable e-records; plan optional MES tags for batches and alarms.

- Roll out cross-shift training with documented SOPs and periodic refresh.

- Schedule preventive maintenance and periodic parameter verification.

Explore Olando K3-2 · See Solution Details · Talk to an Engineer