Configuring Pharma-Grade ODF Production Lines: From Liquid to Finished Film

Share

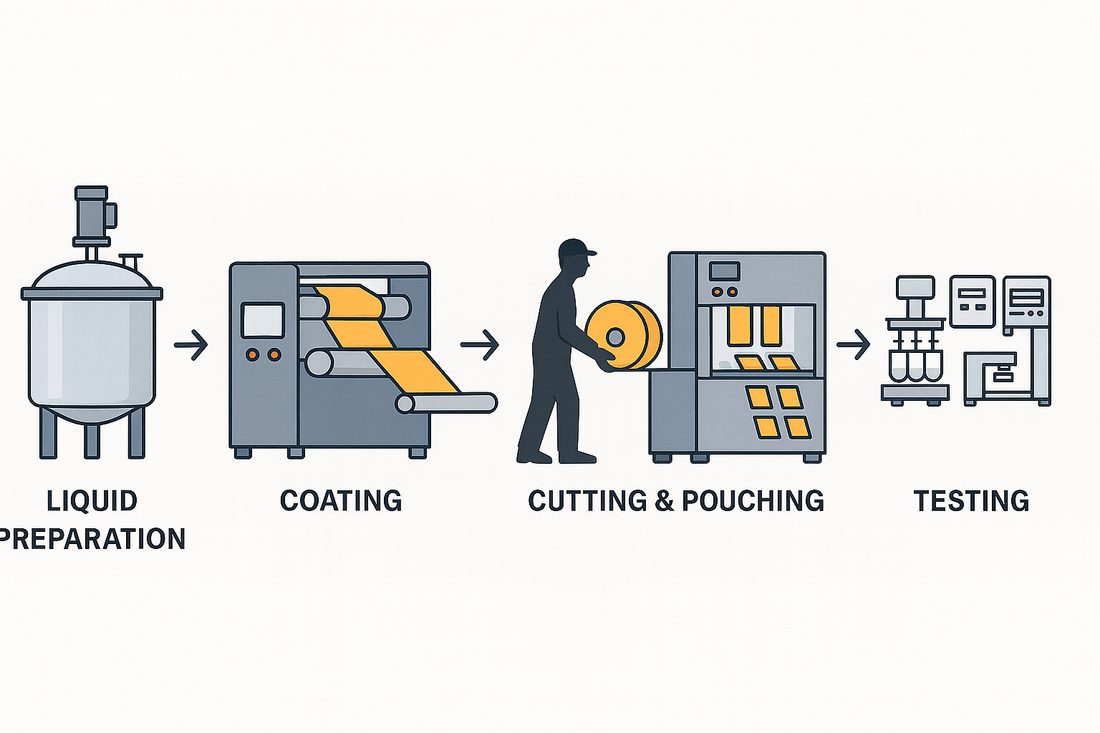

Entering the pharmaceutical market with oral dissolvable films (ODFs) requires more than GMP certification. It demands a closed-loop production system that controls every step—from liquid preparation to film coating, cutting and packaging, and integrated quality testing. This is not simply a set of machines, but a system-level approach to quality, efficiency, and regulatory responsibility.

1) Why Is End-to-End Control Critical for Pharma-Grade ODF?

ODFs differ from conventional dosage forms: they are thin, micro-dosed, and highly sensitive to formulation distribution. Regulatory authorities scrutinize every detail during drug registration, including:

- Traceability of formulation uniformity

- Batch-to-batch consistency of thickness and content

- Sealing integrity and clear identification of packaging

- Complete data records and audit-ready documentation

Only a closed-loop system ensures compliance with these stringent requirements and smooth market entry.

2) Recommended Pharma-Grade ODF Line Configuration

1) Liquid Preparation System

Advanced Pharmaceutical Manufacturing Solutions

- Pharma-grade stainless steel with fully enclosed mixing

- Inline temperature and pH control

- Optional CIP/SIP cleaning modules

- Traceable records of formulation ratios and operations

2) MJ150 Coating System

- Slot-die coating with ±0.02 mm thickness accuracy

- Hot-air gradient drying with automatic tension adjustment

- Full parameter recording: temperature, humidity, speed, tension

- Integration with inline thickness measurement for real-time feedback

3) MJF180 Cutting & Packaging System

MJF180 ODF Cutting & Packaging Machine

- Compatible with aluminum foil, PE films, and multilayer laminates

- Multi-channel cutting, coding, and batch traceability

- Expandable inline weight checking and vision inspection

- Compliant with international packaging traceability standards

4) Integrated Testing Instruments

Pharmaceutical Testing Instruments

- Dissolution, disintegration, thickness, and content uniformity testing

- Data export aligned with FDA 21 CFR Part 11 audit requirements

- Real-time QC platform supporting both production and registration submissions

3) Applications for Pharma-Grade ODF Lines

- OTC drugs: Cough relief, allergy treatment, oral pain relief

- Pediatric and geriatric formulations: Vitamin D, B-complex, sleep aids

- Prescription drugs: High-value formulations with unique absorption pathways

- Export & regulatory projects: Sample production and data packages for EU/US market submissions

Conclusion

ODFs are not just “films”—they are advanced drug delivery systems. A pharma-grade ODF line must integrate liquid prep, coating, packaging, and testing into a closed-loop framework. This ensures GMP compliance, registration-ready data, and global market access. With closed-loop technology, data integrity, and transparent processes, pharma manufacturers can confidently scale ODF innovations into commercial reality.