Patented Hot-Air Drying: Boosting ODF & Transdermal Patch Efficiency by 30%

Share

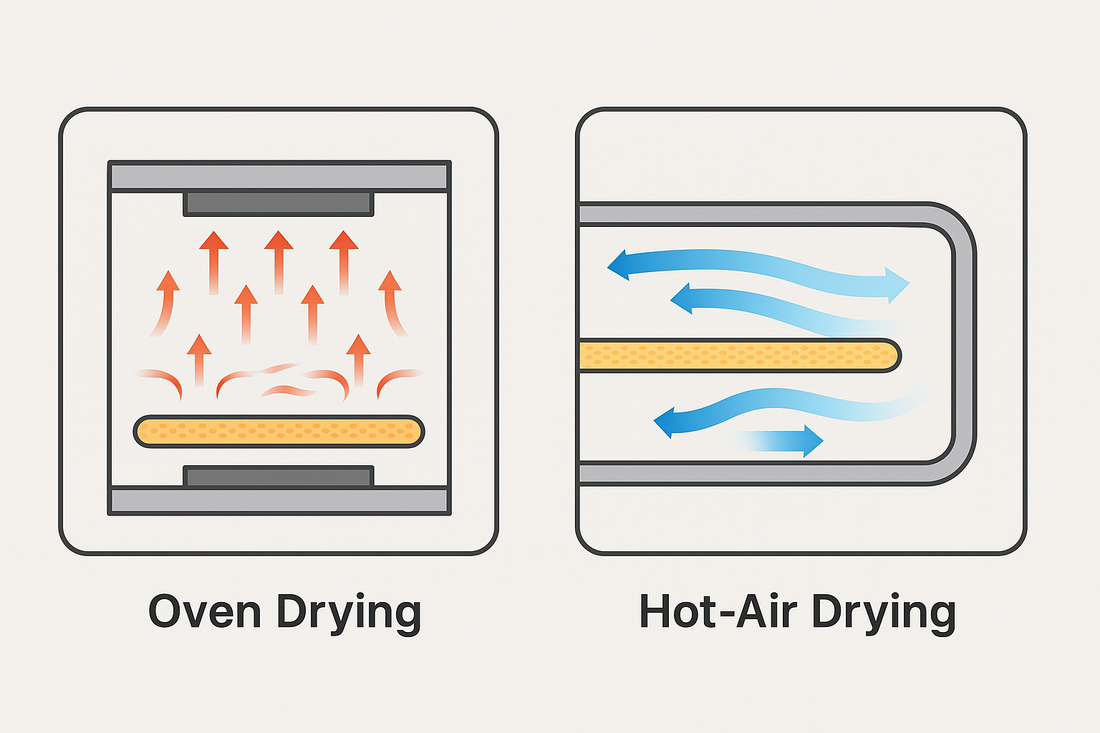

In the large-scale production of oral dissolvable films (ODFs) and solvent-based transdermal patches, the drying process is often the critical bottleneck. Traditional oven-type heating systems, which rely on top and bottom heating plates, frequently struggle to deliver the required efficiency, uniformity, and scalability demanded by modern pharmaceutical manufacturing. To overcome these challenges, Huanghai has developed an exclusive patented hot-air drying technology (CN201668734U), designed specifically for pharmaceutical-grade film production lines.

Industry Pain Points: Why Drying Technology Matters

- Uneven heating with oven plates: Conventional oven heating creates hot spots and temperature fluctuations, often leading to inconsistent film quality.

- Low throughput: Oven-type systems have limited drying efficiency, resulting in longer production cycles and higher operational costs.

- Lack of progressive temperature control: ODFs and patches require a smooth temperature gradient during drying. Oven systems can only achieve stepwise heating changes, requiring frequent manual adjustments.

- Scaling challenges: When moving from pilot-scale trials to full commercial production, oven-based drying fails to maintain consistent performance at higher outputs.

The Huanghai Solution: Patented Hot-Air Drying Technology

Huanghai’s exclusive hot-air drying system (CN201668734U) is engineered to address these challenges head-on. Integrated into the MJ150 ODF & Transdermal Patch Film Making Machine, this patented technology delivers superior performance in large-scale pharmaceutical applications.

Key advantages include:

- Higher heating efficiency & uniformity: Hot-air circulation provides consistent temperature distribution, reducing defects and ensuring stable product quality.

- Progressive temperature control: Supports a smooth transition from hot to mild conditions, protecting sensitive drug formulations and maintaining film integrity.

- 20–30% increase in drying efficiency: Compared to oven-type heating, Huanghai’s system significantly boosts output capacity while lowering energy costs.

- Optional far-infrared heating: Additional modules can be integrated to further enhance total throughput.

- Exclusive competitive edge: This patented system is not available in competing solutions such as oven-type systems from other suppliers, ensuring Huanghai customers benefit from unique performance advantages.

Conclusion

As the pharmaceutical industry continues to demand faster, more reliable, and scalable production of ODFs and transdermal patches, drying technology has become the defining factor for efficiency and compliance. With its patented hot-air drying system, Huanghai provides manufacturers with a powerful tool to achieve higher throughput, superior film quality, and full regulatory compliance.

Discover more about our large-scale MJ150 Film Coating Machine, or contact our team to explore how Huanghai can support your ODF and patch manufacturing needs.