Drying Technology in ODF: Key to Film Stability and Quality

Share

ODF Drying Technology and Film Stability

In the production of Oral Dissolvable Films (ODF), drying is more than a physical process—it’s a critical factor that influences product quality and stability. Parameters like drying speed, temperature gradients, and airflow paths directly impact film uniformity, active ingredient distribution, and final product consistency.

Why Is Drying So Crucial in ODF Manufacturing?

Unlike tablets or capsules, ODFs contain minimal moisture. Even slight deviations in drying can lead to:

- Incomplete film formation—causing cracks or wrinkles

- Migration of active ingredients—leading to dose inconsistency

- Sticky or fragile films—making cutting and packaging difficult

- Compromised shelf life—due to poor long-term stability

That’s why a well-designed drying process is essential to ensure that ODFs are easy to handle, store, and deliver accurate dosage.

Common Drying Techniques for ODF

- Hot Air Convection Drying: The most common method, cost-effective and suitable for general ODF lines.

- Infrared/Far-Infrared Heating: Ideal for temperature-sensitive APIs, accelerates drying efficiency.

- Vacuum or Low-Temperature Dehumidification: Best for high-value or moisture-sensitive formulas—though more costly.

Huanghai’s Approach: Gradient Drying for Stability

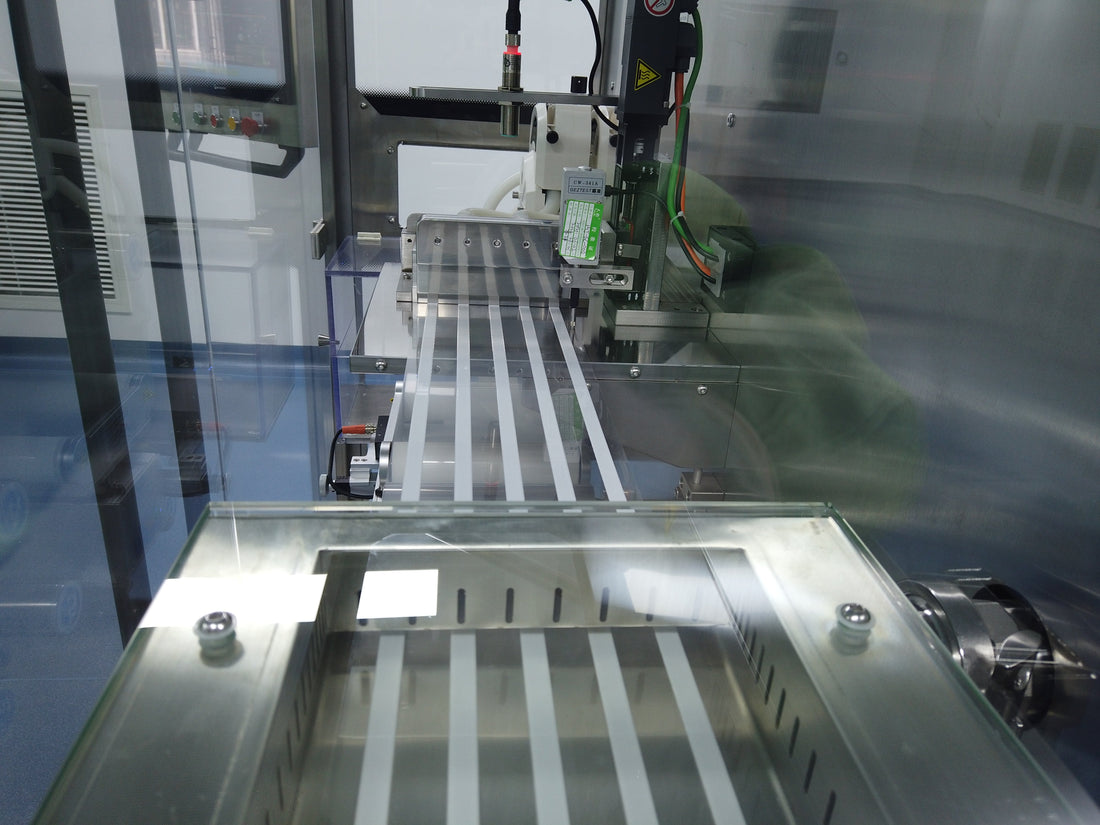

Our equipment features a hot air drying tunnel with optimized duct length and airflow paths. This design naturally forms a temperature gradient—from high to low—ensuring gentle transitions that preserve membrane integrity and reduce internal stress.

How to Evaluate Drying Quality?

To ensure drying success, we recommend measuring:

- Film thickness consistency (to check for uneven drying)

- Content uniformity (to ensure even API distribution)

- Residual solvent levels (especially for solvent-based formulations)

- Low-temperature storage stability (to simulate shelf-life conditions)

Conclusion

Drying process design is not only crucial for manufacturing efficiency but also for regulatory compliance and market acceptance. Manufacturers should prioritize equipment with adjustable temperature zones, balanced airflow, and stable tension control—paired with robust quality detection tools for a closed-loop production system.