Coating High-Viscosity Formulations: Challenges and Solutions

Share

As oral dissolvable films (ODFs) and transdermal patches evolve with multi-component, sustained-release, and functional ingredients, more clients are requesting coating solutions for high-viscosity, high solid content, and non-Newtonian fluids. These formulations place higher demands on coating systems. Conventional equipment often struggles with issues such as thickness variations, film breakage, bubbling, and misalignment. Overcoming these challenges requires systematic optimization across liquid supply, die design, and tension control.

1. Common Coating Challenges with High-Viscosity Formulations

- Poor fluidity: Difficult to spread evenly, leading to buildup or film breakage in the coating zone.

- Thickness instability: Sensitive to temperature and pressure, resulting in uneven thickness across batches.

- Foaming: Entrapped air bubbles are harder to release, causing rough film surfaces after drying.

- Edge leakage: Wide-width coating may cause material to overflow at die edges, contaminating rollers or destabilizing tension.

2. HUANGHAI’s Solutions for High-Viscosity Coating

To handle complex formulations with viscosities above 10,000 cps, HUANGHAI equipment integrates the following innovations:

- Closed liquid supply system: Minimizes shear force and air intake while stabilizing pressure output.

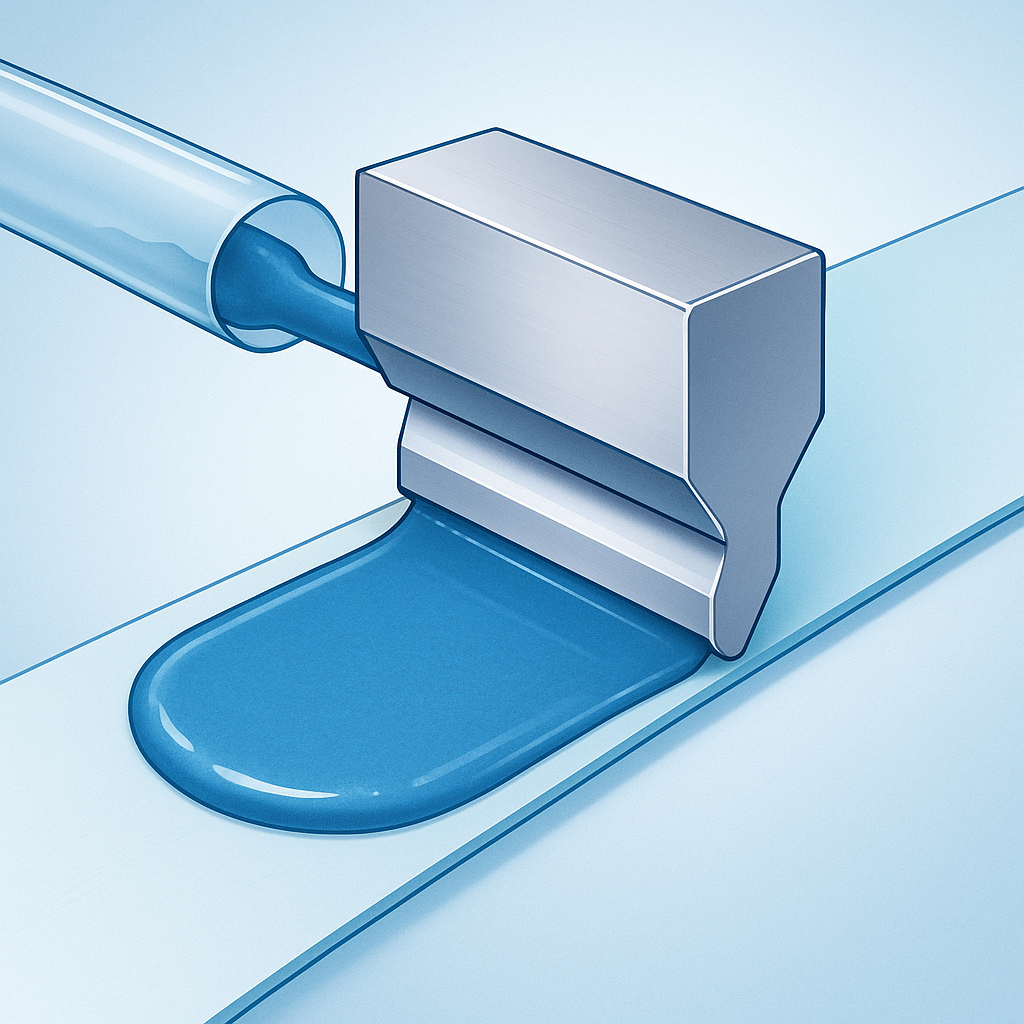

- High-precision slot die: Customized die gap control with ±2μm accuracy, adaptable to different viscosities.

- Intelligent tension control: Real-time feedback with auto web-guiding to maintain film stability.

- Heated modules: Die head and feed pipelines can maintain 30–60°C for improved flowability and clog prevention.

- Optional foam elimination module: Supports inline degassing or optimized pre-mixing for bubble-prone formulations.

Recommended Model:

3. Application Scenarios for High-Viscosity Coating

- Nutritional films / sugar-loaded ODFs: High sweetener or thickener content.

- Sustained-release drug films: High-viscosity polymers to control release profiles.

- Traditional medicine ODFs: Extract-based formulations with sticky concentrates.

- Industrial topical patches: Muscle or joint patches often containing viscous matrix materials.

Conclusion

High-viscosity formulations bring both higher value and greater technical complexity. Only coating systems that optimize liquid handling, die precision, and process control can truly meet the demands of these challenging applications. HUANGHAI delivers not ju