What Is FDA 21 CFR Part 11 and Why It Matters for Pharmaceutical Equipment

Share

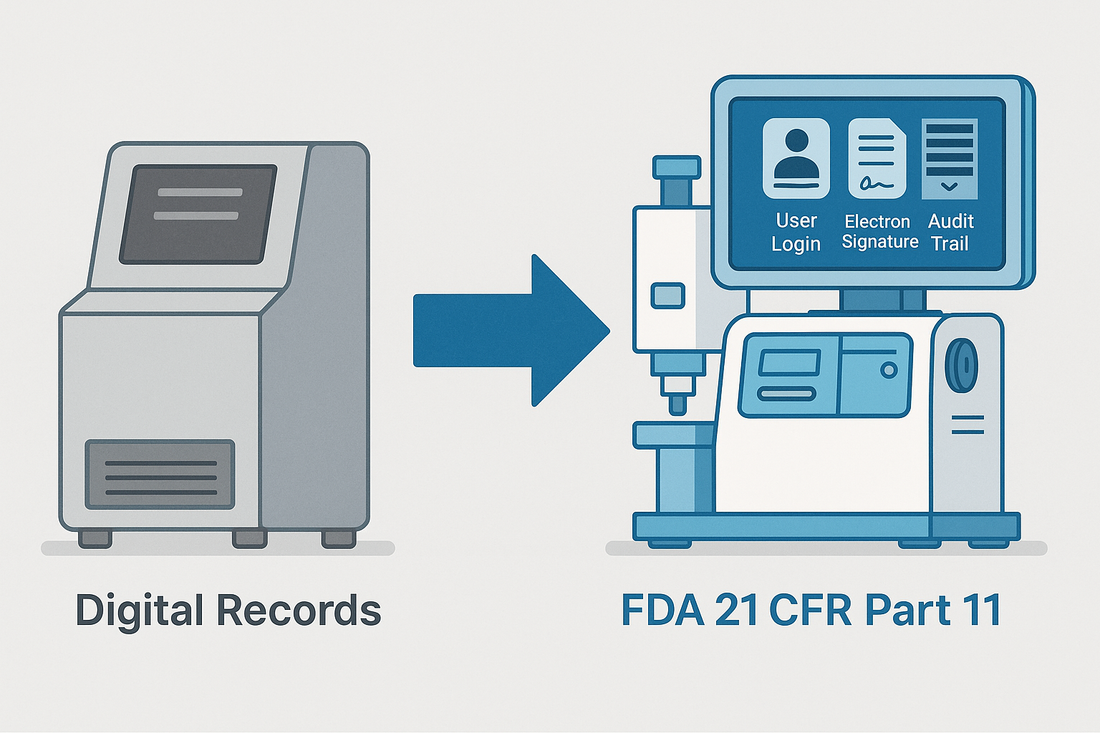

Introduction: As pharmaceutical manufacturing becomes increasingly digital, regulators are focusing on the integrity, completeness, and traceability of electronic data. The U.S. FDA’s 21 CFR Part 11 defines the rules for electronic records and electronic signatures. It has become a global benchmark and a “passport” for pharmaceutical equipment entering the U.S. and European markets. This article breaks down its core requirements and explains why equipment manufacturers must design compliance into their systems from day one.

Common Compliance Misconceptions

- Assuming that a touchscreen or data export function automatically qualifies as “digital compliance.”

- Ignoring mandatory requirements for user access control and audit trails.

- Lacking the ability to generate system logs, electronic signatures, or restore original data.

- Attempting last-minute fixes during registration or client audits—often costly and disruptive.

How to Achieve Part 11 Compliance via Equipment Design

- User Access Control: The system must support hierarchical permissions and login authentication.

- Audit Trail: Every operation must generate a traceable log of who did what, and when.

- Electronic Signatures: Each record must be linked to a verified operator identity and timestamp.

- Data Integrity: Recorded data must be tamper-proof, with secure export and long-term archiving.

- Software Validation: Systems must support IQ/OQ documentation and validation testing.

HUANGHAI’s Approach to Part 11 Compliance

HUANGHAI integrates full Part 11 support modules across its coating, laser drilling, and testing systems:

- Linux-based control software: Supports user role management, automatic audit logs, and data backup.

- Automated recordkeeping: All parameter changes are automatically recorded with operator name and timestamp.

- Hardware flexibility: Customers may specify Siemens or equivalent PLCs to align with local validation practices.

- Documentation & training: IQ/OQ validation files and on-site training are provided to support audits and system qualification.

Beyond Software—Compliance as Design Philosophy

Part 11 compliance is not just a “software feature” but a reflection of regulatory understanding at the design level. Embedding compliance early improves both audit readiness and market access speed. HUANGHAI helps customers build data integrity directly into the equipment lifecycle, from configuration to production reporting.

Key Takeaway

FDA 21 CFR Part 11 ensures that electronic records and signatures are trustworthy, secure, and traceable. Equipment that supports access control, audit trails, and validated data handling doesn’t just meet regulatory expectations—it enables reliable, compliant, and future-ready digital manufacturing.

To learn more or request our Part 11 compliance white paper, contact the HUANGHAI technical team.