Why Dissolution Testing Is Critical for Oral Dosage Forms

Share

Introduction

Dissolution testing is a core element of quality control in the manufacturing of oral solid dosage forms such as oral dissolvable films (ODFs), tablets, and capsules. It directly impacts bioavailability and is a regulatory requirement for product registration and market approval. For manufacturers targeting both supplements and pharmaceuticals, it is essential to use dissolution testers that meet pharmaceutical-grade GMP standards.

1. Why Is Dissolution Testing So Important?

- Simulates in vivo drug release: Dissolution tests replicate environments like the oral cavity or gastrointestinal tract to assess release profiles.

- Guides formulation optimization: Testing results inform adjustments in excipients and processing parameters to achieve desired performance.

- Required by global pharmacopoeias: Regulatory bodies such as USP, EP, and ChP mandate dissolution data for market registration.

2. Common Challenges in Dissolution Testing

- Inconsistent temperature control causing test result variability

- Manual sampling errors leading to poor reproducibility

- Lack of automated data recording impacting traceability

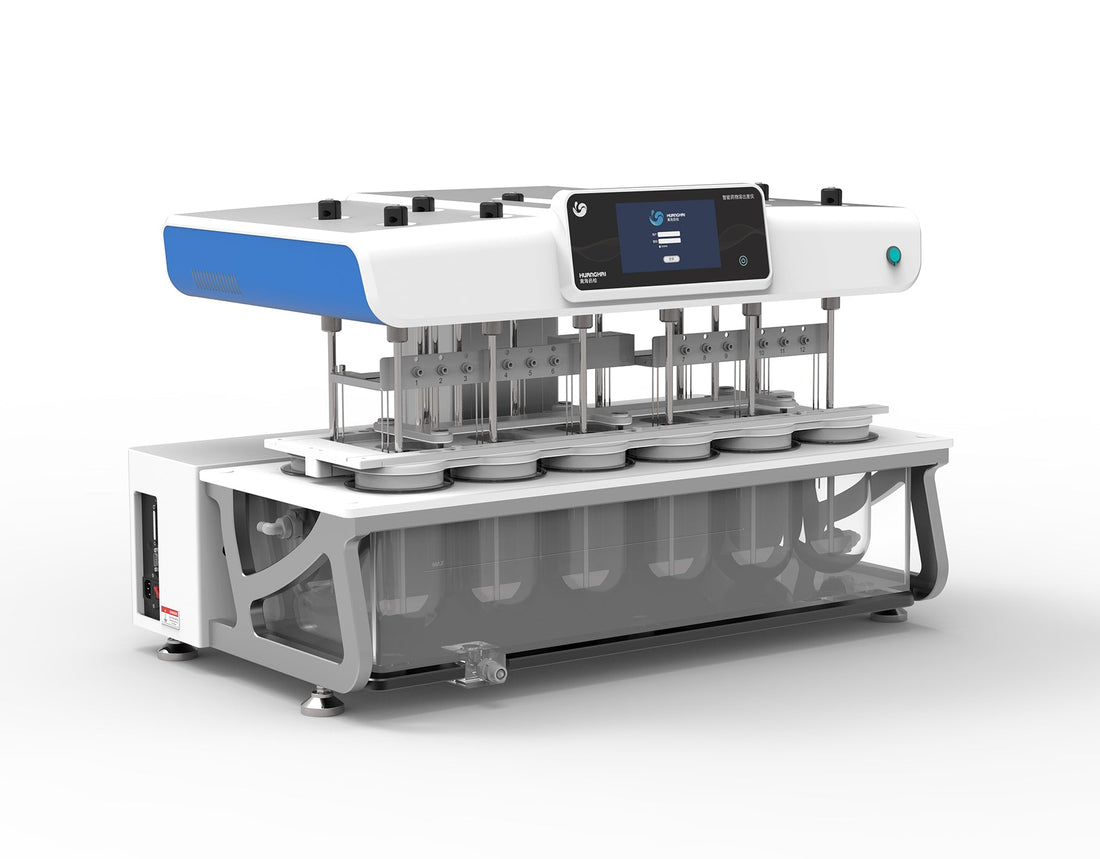

3. HUANGHAI’s Dissolution Testing Solution

- Pharma-grade design: All material contact parts meet GMP requirements, suitable for both dietary supplement and drug production.

- Smart temperature control & auto-sampling: Ensures stable and repeatable test conditions.

- Full electronic data capture: Enables complete traceability for audits and export registration.

- Versatile application: Supports testing for ODFs, tablets, sustained-release formulations, and functional nutraceuticals.

Conclusion

Dissolution testing is not just a quality control tool—it’s a compliance enabler that spans R&D, regulatory filing, and production. Choosing a GMP-compliant dissolution tester ensures your product meets international standards and accelerates your path to market.